- Cement

- Construction

- Sustainable development

-

-

Sustainable development

-

-

- About Us

- Contact Us

Sustainable development

Synergia

> Sustainable development > Synergia

Synergia Process

Exclusive to Ciment Quebec Inc. (CQI), Synergia™ is a unique “green” cement production process in North America. Synergia™ combines professional know-how, modern equipment, an innovative infrastructure, advanced techniques focused on energy efficiency, and the reduction of the carbon footprint for cement production.

Compared with the average for Quebec’s cement industry, the Synergia™ process of Ciment Quebec Inc. requires 30% less combustible energy during production, and generates up to 10% fewer greenhouse gases than competing clinkers and cement. Synergia™ allows up to 60% replacement of commonly used fossil fuels with alternative fuels. The process is in accordance with the air quality regulations of the Ministère du Développement durable, de l’Environnement et de la Lutte contre les changements climatiques (MDDELCC).

Cement production releases carbon dioxide (CO2) into the air in two stages: during decarbonation of the raw meal (finely ground limestone) and during fuel ignescence required to heat the raw meal. There is no technology that allows reduction of the CO2 emanations inherent in the process of transforming limestone into clinker. Calcination of limestone is an intrinsic step to the chemical transformation of it to transform it into clinker and then into cement. CO2 emissions from decarbonation (process emissions) represent more than 65% of all CO2 emissions generated by the cement plant, and cannot be reduced.

CO2 emissions from using combustible fuels are also hard to avoid, since the heat energy required for chemical transformation of the material is produced by this fuel. However, CQI is working to reduce as much as possible the carbon footprint resulting from combustion, by increasingly using various combustible materials instead of traditional fossil fuels, such as coal, natural gas, and heavy oil.

CQI heavily invested in alternative fuels, one of the cornerstones of the Synergia™ production process – one of the greenest processes in the world. The Synergia™ process involves:

1 – Waste Material Recycling Centre

CQI owns and operates a large-capacity waste material recycling centre –the only one of its kind in the world in terms of its size and setup—on the plant site. The Centre receives and conditions large volumes of different waste materials, which are then stored and dosed based on their energy recovery during the pryo-process in the cement plant. In addition to the used tires and oils commonly found in the cement industry, the CQI’s Centre processes materials such as biomass, asphalt shingles, multi-plastic waste, and treated wood. Its processing capacity is over 50,000 tonnes of waste material per year. Materials that cannot economically be recycled avoid ending up in landfills and are recycled as energy in the cement production process. Using these replacement fuels considerably reduces greenhouse gas emissions (GGE) related to the use of fossil fuels.

2 – Eco-Furnace

Unique in North America, CQI’s eco-furnace is used to extract the energy potential from used tires and other alternative fuels from the Waste Material Recycling Centre.

This energy is used in the pyro-processing and contributes to the calcination of the raw meal.

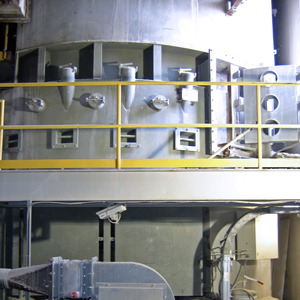

3 – Multi-Cyclone Preheater with Extended Calcining Furnace

The multi-cyclone preheater with the extended calcining furnace, located upstream of the rotary kiln, is highly effective at transferring heat between the rising hot gases and the descending raw meal. Its purpose is to calcinate and raise the temperature of the raw meal to 900? before it enters the kiln. Through a series of cyclones, the preheater with extended calcining furnace optimizes the exchange of hot gases with the raw meal. In addition, it recovers energy from the eco-furnace, rotary kiln and clinker cooler to provide optimal energy efficiency. CQI is the only cement plant in Quebec to have this type of equipment, which maximizes combustion while reducing the use of combustible energy.

4 – Short Rotary Kiln

Unlike a cement plant conventional oven that is approximately 120 metres long, the rotary kiln at CQI is 42.7 metres long and is a rotary kiln with the lowest length-diameter ratio in the world. With its optimized upstream heating equipment, the short kiln transforms raw meal into clinker within a very limited retention time.

Sustainable development

A responsibility which means a lot

To us at Ciment Quebec inc, sustainable development is a responsibility which means a lot. We invested massively in the cement manufacturing process to make it eco-efficient. Our Synergia™ process is quite unique. We also compensate for the greenhouse gas emissions of our representatives on the road and other work-related travels. We encourage citizens’ initiatives in the communities where we are established. We work with engineers and contractors to bring their projects of sustainable development to a successful conclusion.